The Solar Energy Research Institute of Singapore (SERIS) at NUS is embarking on a series of research projects over the next 10 years to strengthen and deepen its solar capabilities.

Three flagship R&D projects

(1) Perovskite-silicon tandem solar cells and modules

Prof Armin ABERLE (Project Leader), Assoc Prof Erik BIRGERSSON, Asst Prof HOU Yi, Dr Firdaus BIN SUHAIMI, Dr CHOI Kwan Bum, Dr JANG Yu Jin, Dr KIM Jinhyun, Dr LUO Chao, Dr Romika SHARMA, Dr WANG Puqun, Mohd Asri BIN MOHD HAMDAN, Gabby Alonzo DE LUNA, Elisaveta UNGUR PhD students: Varsha DAHIYA, DU Xinyi, Stella HADIWIDJAJA, LEE Ling Kai, Erik SPAANS, YAP Qi Jia, ZHOU Qilin

Introduction

Singapore’s space constraints necessitate the installation of solar PV systems with very high efficiencies to maximise PV power generation. While single-junction crystalline silicon (Si) solar cells have a theoretical efficiency limit of about 30% under the standard 1-Sun solar spectrum (AM1.5G), stacking a second solar cell with a larger electronic bandgap onto a silicon cell to create a two-junction (or “tandem”) solar cell offers the potential for much higher power conversion efficiencies while maintaining low manufacturing costs ($/W). For 2-junction Si-based tandem solar cells the theoretical 1-Sun efficiency limit is about 44%, whereby a practical cell efficiency limit of around 35% seems possible in future mass production (beyond 2030). Due to this excellent PV efficiency potential, Si-based tandem solar cells are of very high importance to Singapore’s solar sector, for both manufacturing and deployment. This flagship project focuses on exploring low-cost wide-bandgap thin-film materials, in particular

metal halide perovskites, as the absorber layer of the top cell on a silicon bottom cell. In 2025 our research efforts focused on the improvement of perovskite-Si tandem cells with small (1 cm²), medium (16 cm²) and large (244 cm²) areas, the improvement of the efficiencies of our 1-cell mini-modules with active areas of up to 244 cm², and outdoor monitoring of encapsulated tandem mini-modules to study their long-term reliability in Singapore’s tropical climate.

Small (1 cm²) perovskite-Si tandem solar cells on textured Si bottom cells

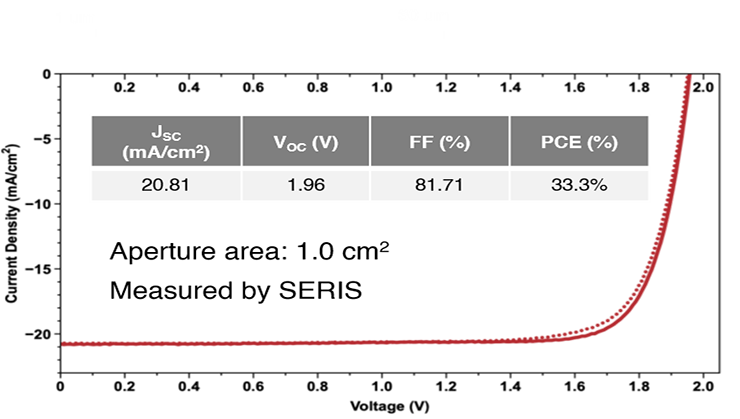

In 2025, SERIS’ Perovskite-based Multijunction Solar Cells Group achieved 33.3% efficiency for a perovskite-silicon tandem solar cell using an industrially fabricated Cz heterojunction silicon bottom cell with cell area of 1 cm², see Fig. 1. The measurement was performed at SERIS. This was accomplished by successfully forming high-quality 1.66-eV perovskite films on textured silicon surfaces using the spin-coating method. A key challenge in this work was improving the perovskite crystal quality on silicon architectures. We introduced a ligand that effectively controls the principal organic cations to regulate crystallisation. Our organic control approach supplements previous strategies mainly focused on strong coordination with inorganic lead halides, enabling refined crystal growth and improved film quality of perovskite films on thin Si wafers. We effectively minimised the quality gap between perovskite films grown on glass and those grown on thin Si substrates, thereby enabling high-quality wide-bandgap perovskite films being integrated with industrially fabricated Cz silicon bottom cells. The group’s ongoing efforts are focused on closing the gap to the current world-record 1cm² perovskite-silicon tandem solar cell (34.8%, LONGi, China).

Fig. 1: Measured J-V curves of a 33.3% efficient perovskitesilicon tandem solar cell (1.0 cm2 aperture area) made at SERIS using a Cz heterojunction silicon bottom cell. The silicon cell has pyramid-textured front and rear surfaces. The perovskite absorber was made by spin coating.

Upscaling of perovskite-silicon tandem solar cells to medium and large areas (16 and 244 cm²)

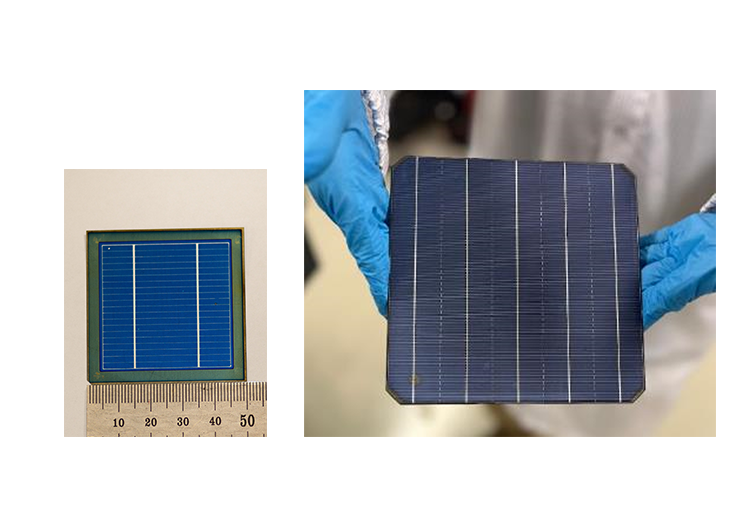

In 2025, SERIS’ NISCM Cluster continued to make good progress with improving the PV efficiencies of perovskite-silicon tandem solar cells with active areas of 16 and 244 cm², as shown in the photographs of Fig. 2. Both the silicon bottom cells (heterojunction, Cz wafers) and the perovskite top cells were fully made in SERIS. A low-temperature screen-printed silver metallisation was utilised on both sides of the 2-terminal (2T) tandem solar cells.

Fig. 2: Fig. 2: Photographs of SERIS-made perovskite-silicon 2T tandem solar cells. Left: 16-cm² (active area) device on a 25-cm² smooth silicon substrate. Right: M2-size (244 cm²) full-wafer tandem cell with textured silicon surface.

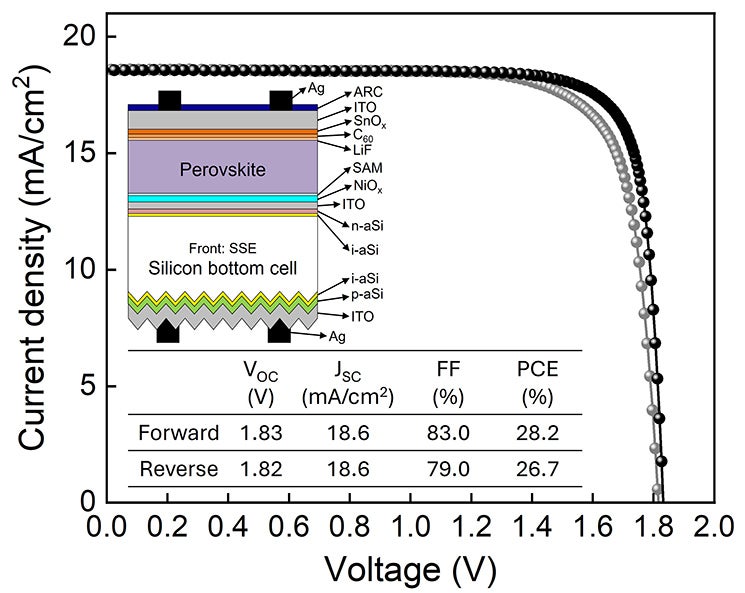

The current-voltage curves of a 16-cm² tandem cell measured at SERIS and a schematic of the cross-sectional device structure are shown in Fig. 3. The cell has an efficiency of 28.2%, which is a very good result considering that the top surface of the silicon bottom cell is smooth (i.e., not textured), which limits the current that can be generated by the silicon cell. The top cell’s perovskite absorber layer has a bandgap of 1.68 eV and was deposited using the spin-coating method. During spinning the wet precursor film spreads uniformly across the surface and undergoes rapid and controlled crystallisation, leading to large well-formed crystal grains with few defects. This results in a high electronic quality of the absorber layer and enabled the NISCM team to achieve more than 28% tandem cell efficiency on 16 cm², up from 25% a year earlier.

Fig. 3: Measured 1-Sun J-V curves of a 28.2% efficient perovskite-silicon 2T tandem solar cell with active area of 16 cm². The inset shows a schematic cross section of the device structure. The heterojunction Cz silicon bottom cell has a smooth front surface and a pyramid-textured rear surface. The perovskite absorber was made by spin coating.

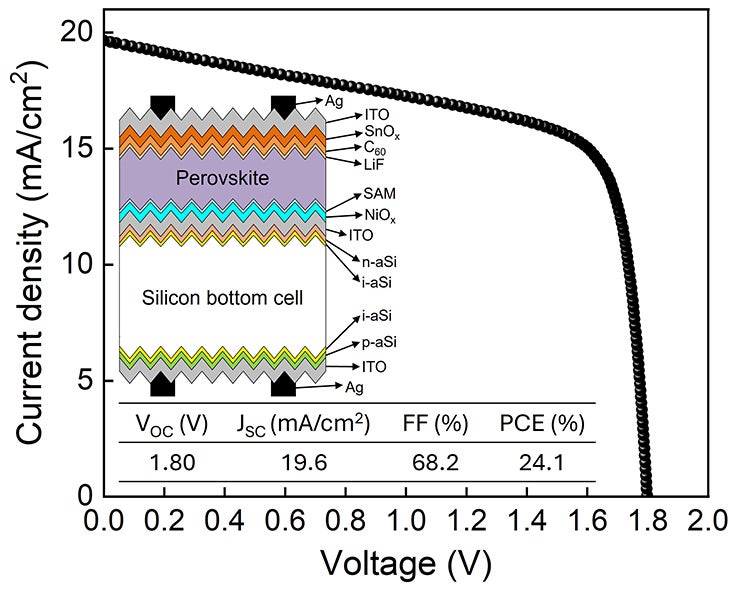

Fig. 4: Measured 1-Sun J-V curve of a 24.1% efficient perovskite-silicon 2T tandem solar cell with an area of 244 cm² (M2 size wafer). The heterojunction Cz silicon bottom cell has pyramid-textured front and rear surfaces. The perovskite absorber was made by a 2-step hybrid dry-wet processing sequence.

Using SERIS-made heterojunction silicon bottom cells on M2-size (244 cm²) Cz wafers with pyramid texture on both surfaces, the NISCM Cluster achieved 24.1% tandem cell efficiency in 2025, up from 20% a year earlier. The M2-size perovskite absorber layer of the top cell was produced via a 2-step hybrid dry-wet processing sequence, providing compatibility with upscaling to industrial wafer sizes and mass production workflows. The current-voltage curve of the 24.1% tandem cell and a schematic of its cross-sectional device structure are shown in Fig. 4. As can be seen, the open-circuit voltage (1.80 V) is good, but the fill factor is still rather low (~68%) due to a shunting issue. The NISCM Cluster’s ongoing efforts are focused on eliminating this top cell shunting issue and improving the tandem cell efficiency to more than 30%.

These achievements make SERIS the only facility in Singapore, and one of only a few labs in the world, capable of producing fully in-house fabricated high-efficiency perovskite-silicon 2T tandem solar cells on industrial-size silicon wafer substrates. In terms of power conversion efficiencies, SERIS maintained its position in 2025 as one of the top labs in the world for small (1 cm²), medium (~20 cm²) and large-area (> 200 cm²) 2-junction perovskite silicon tandem solar cells.

Development and upscaling of perovskite-silicon tandem cell mini-modules

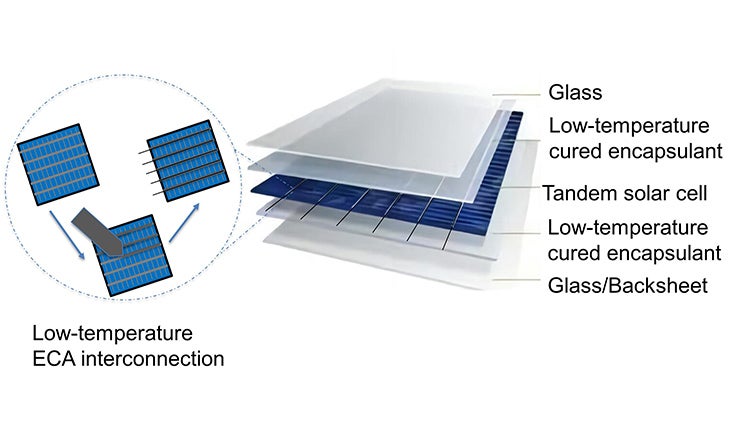

In 2025, the project’s module team continued its work on the scaling of perovskite-silicon tandem cell mini-modules from lab-scale devices (1 cm²) to M2-size (244 cm²) prototypes. This process requires significant adaptation of our fabrication methods to meet the low thermal budget requirements imposed by the perovskite top cells. The Bill of Materials (BOM, see Fig.5) was optimised to ensure compatibility with low temperature processes below 120°C, without sacrificing efficiency.

Fig. 5: Bill of Materials (BOM) for low-temperature fabrication of perovskite-silicon tandem cell modules.

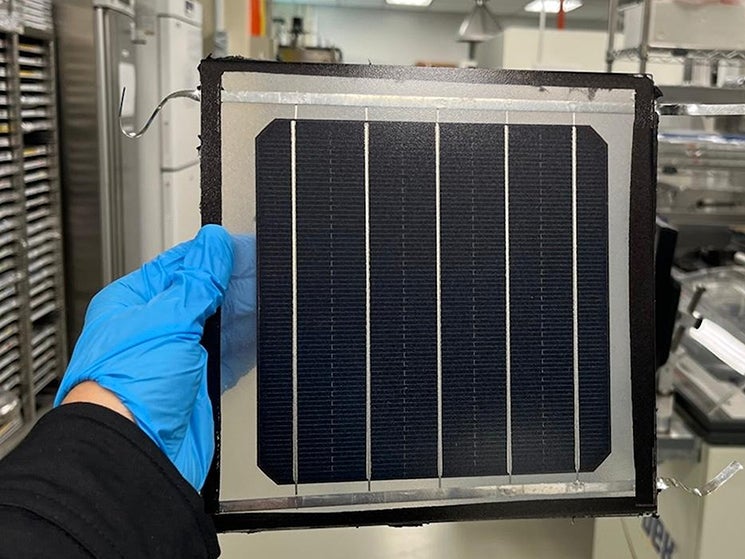

The main achievement in 2025 was the fabrication and testing of M2-size perovskite silicon 1-cell tandem mini-modules with efficiencies of more than 21%, up from 16% a year earlier. Figure 6 shows a photograph of one of these fully in-house fabricated 244-cm² tandem mini-modules featuring low-temperature encapsulation and interconnections. This efficiency result was obtained through significant improvements in low-temperature encapsulation and interconnection technologies, specifically designed to meet the stringent temperature requirements of perovskite layers while reducing thermal stress and protecting structural integrity. The team screened and evaluated thermoplastic polyolefin (TPO) encapsulants for compatibility with perovskite layers, demonstrating high optical transmittance and minimal degradation after damp-heat testing, which is comparable to or better than that of conventional encapsulants. Stencil printed electrically conductive adhesives (ECAs) were optimised for low-temperature interconnections, enabling strong adhesion while minimising cell-to-module (CTM) losses.

Fig. 6: Photograph of a fully in-house fabricated 244-cm² (M2- size) perovskite-silicon 1-cell tandem mini-module featuring low-temperature encapsulation and interconnections.

In 2025, the module team achieved the following technical milestones:

• Over 21% efficiency (with CTM losses of ~5%) for M2-size 244-cm² 1-cell tandem mini-modules. Using advanced materials (BOM) and encapsulation methods, we maintained the structural integrity and performance of these minimodules, marking an important step forward on the path to commercialisation of perovskite-silicon PV technology.

• Outdoor testing of tandem cell mini-modules (see Fig. 7): We started our outdoor tandem-cell mini-module testing activities at the NUS Rooftop Testbed in tropical Singapore in December 2024, using in-house fabricated tandem mini-modules. The initial tests highlighted the need for a stricter Bill of Materials in hot-humid conditions. In September 2025, the second batch of tandem mini-modules with optimised BOM for the tropics was deployed for continuous Jsc logging, temperature/irradiance monitoring, and monthly indoor stabilised I-V and spectral response measurements. Initial results show no significant degradation, with continuous monitoring ongoing to validate long-term stability.

• Indoor stability testing of tandem mini-modules: In June 2025, we initiated indoor testing of tandem modules under accelerated stress conditions. This includes damp-heat exposure, thermal cycling, and continuous maximum power point tracking (MPPT) under controlled irradiance and temperature conditions. We use in-house fabricated perovskite-silicon 1-cell tandem mini-modules for these tests. The primary aim is to identify possible degradation pathways and failure modes. We also aim to correlate these findings with outdoor data to provide accurate module lifetime predictions.

Fig. 7: Perovskite-silicon tandem mini-modules deployed at the NUS Rooftop Testbed for outdoor testing in Singapore’s hot-humid tropical climate.

Path Forward: Towards a 60-cell perovskite-silicon tandem module

The R&D roadmap of this flagship project involves the scaling up of 1-cell perovskite-silicon tandem mini-modules to 60-cell (~1.7m²) tandem modules by March 2027. Current efforts are focused on improving the durability of the low-temperature encapsulants and ECAs while adapting the processes to industry-compatible methods. We are conducting climate chamber testing and MPPT testing under controlled illumination and temperature conditions to refine our processes and improve the PV efficiency and durability of these novel tandem modules. This is complemented by ongoing outdoor testing of the prototype modules in Singapore’s hot and humid tropical climate, with emphasis on correlating indoor (damp heat, thermal cycling, and MPPT) and outdoor field data to predict degradation rates and guide BOM choices. Overall, this tandem flagship project is progressing well and is making major contributions to bringing the perovskitesilicon tandem PV technology closer to commercial viability, with the potential to deliver very-high-efficiency (30%) PV modules optimised for space-constrained environments like Singapore.

(2)Building-integrated Photovoltaics (BIPV)

Dr Carlos CLEMENT, Dr CHEN Tianyi, Srinath NALLURI, Rupendra ARYAL

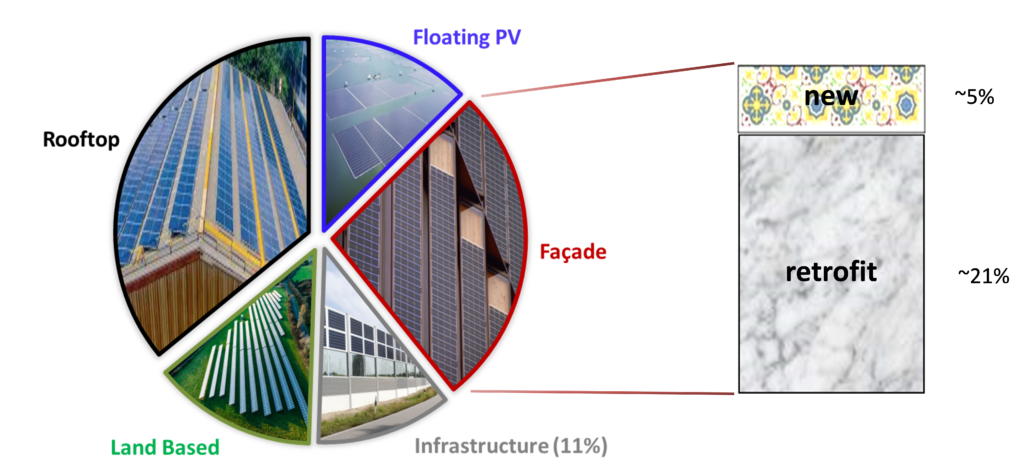

Solar deployment in Singapore has grown exponentially, from an installed capacity of 429 MWp (Megawatt-peak) of photovoltaic (PV) panels in 2020 to 1.4 GWp in 2024. At the current rate, the nation is projected to exceed its target of at least 2 GWp (Gigawatt-peak) installed capacity by 2030. However, this translates to only about 3% of Singapore’s annual electricity consumption, and there remains a need to expand PV deployment more aggressively. Singapore has an estimated PV installation capacity of 8.6 GWp within its territorial boundaries. Of this, approximately one third is attributed to rooftop PV (see Fig. 1), which is also the predominant form of PV deployment here.

Fig. 1: Distribution of PV installation capacity in Singapore

Fig. 1: Distribution of the techno-economic solar potential for PV deployment based on the Solar PV Roadmap of Singapore 2020.

While there still remain significant unexploited rooftop spaces, several challenges could hinder the full uptake of its potential, for example competing uses with building utilities (M&E equipment, chillers, antennas) or an increasing trend towards green roofs. Therefore it is ever more important and timely to address the second-largest solar potential shown in Fig. 1, which are façade areas by means of Building-integrated PV (BIPV) or Building-added PV (BAPV), collectively termed BIPV here. The techno-economic potential for facades entails an estimated 13.98 km2 of deployable area (~38% of total PV potential), however there are major barriers for the adoption of BIPV, including reluctance from architects due to concerns about aesthetics, higher costs, fire safety and integration complexity.

Aesthetic PV and test-bedding

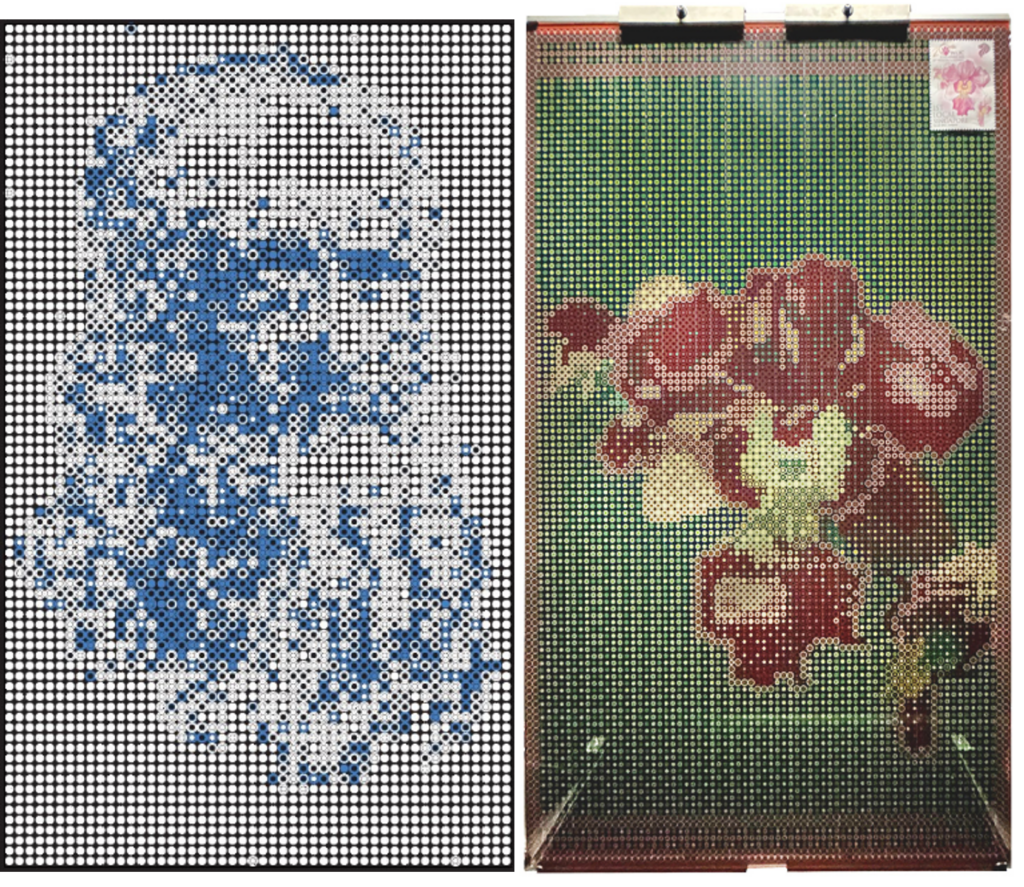

To address the key issue of aesthetics, SERIS had previously introduced a novel colouring method for PV modules, called the “Peranakan PV” modules, which allows to create complex and heterogeneous images on panels with minimal optical loss and no current mismatch. More recently, the team further evolved another colouring method, the pointillism-inspired PV modules, that follow an algorithm that translates non-repeated images into a format suited for printing on BIPV modules, adding further design flexibility (see sample in Fig. 2). Through the guided light transmission properties of the inks, and proper design of the colour points, uniform light transmission throughout the entire PV module is maintained and consequently the modules are also hot-spot free.

Fig. 2: Mismatch-free pointillism PV panels with various images such as the portrait of Leonardo da Vinci (left) and the Singapore national orchid (right).

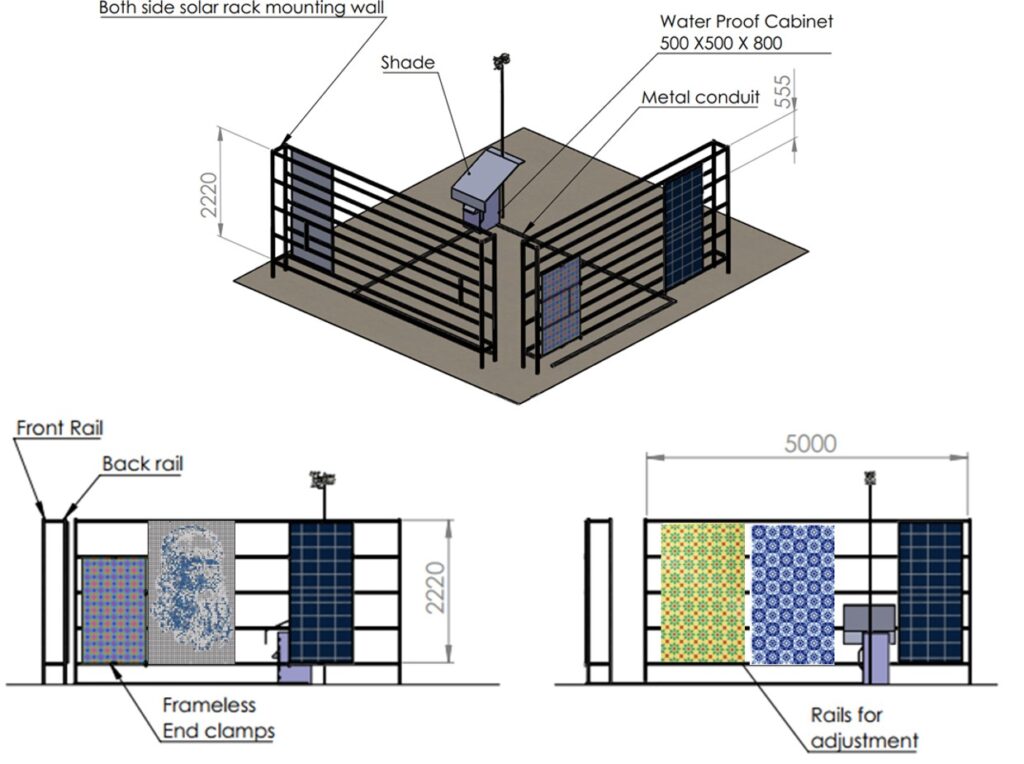

In 2024, we initiated the design and construction of a dedicated testbed on the rooftop of SERIS’ CleanTech One facility. This setup is meant for outdoor monitoring of BIPV systems (see Fig. 3), incorporating versatile attachment points and a modular, swappable façade system. The testbed will serve as a platform for advancing BIPV technology, enabling comprehensive evaluation of various solutions under real-world conditions, with the advantage of rapid plug-and-play testing.

Fig. 3: Proposed BIPV outdoor testbed for façade systems. The testbed will be used to evaluate various technologies as well as mounting and interconnection strategies.

Building information modelling (BIM)

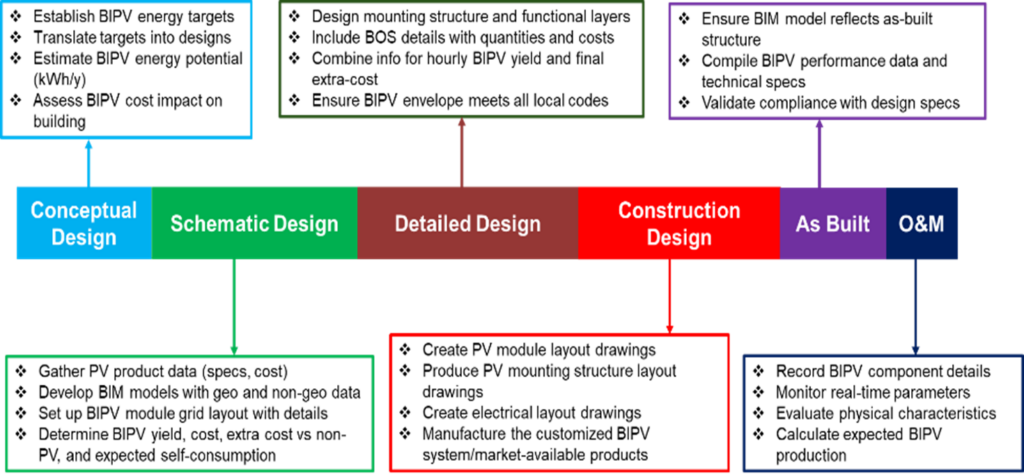

Another key challenge for BIPV adoption is the lack of a digital workflow within the standard BIM (Building Information Modelling) framework to streamline design and execution processes across project stages. The BIM system entails creating and managing digital representations of a building's physical and functional characteristics (“digital twin”). This includes geometric models, time scheduling, cost and energy estimates and building operations.

Fig. 4: BIPV-specific tasks integrated at each project stage along the BIM workflow

In 2024, we developed a BIM-based framework tailored to Singapore, integrating BIPV tasks into the existing BCA process across the six project stages (see Fig. 4). This framework includes precise Level of Development (LOD) specifications for BIPV components, covering geometric attributes like dimensions and textures, and non-geometric data such as electrical properties, certifications.

The approach ensures a seamless transition from conceptual design to operation, promoting better collaboration among stakeholders while improving efficiency and cost effectiveness. Our efforts will focus on building a digital BIPV component library, enabling accurate energy generation simulations and optimised façade performance within the BIM environment. This work supports Singapore’s drive for low-carbon buildings under the SG Green Plan 2030.

BIPV Displays

Our efforts to advocate for BIPV as an attractive and viable solution for Singaporean facades include show-casing innovative displays at major events. During the 2024 National Day Parade (NDP) in August, we showed a special edition of a “Singapore flag made of solar panels”, using digital ceramic inks and made from bifacial heterojunction solar cells, produced in collaboration with REC Solar Pte Ltd. This unique piece (see Fig. 5) was displayed at the NDP Bishan Heartland Exhibition and highlights the potential of BIPV as a prominent architectural feature.

In October, for the Singapore International Energy Week, we fabricated solar panel displays featuring the SIEW and ACES logos (see Fig. 6 for the SIEW logo), demonstrating the versatility of BIPV technology. Additionally, at the inaugural Ministry of Defence Sustainability Day, we presented our patented Peranakan PV and pointillism PV designs, further promoting the diverse applications and aesthetic possibilities in innovative urban architecture.

Fig. 5: Singapore Special Edition BIPV flag at the Bishan Heartlands Exhibition during the 2024 National Day Parade.

Fig. 6: SIEW logo made from BIPV panels, displayed at the main SIEW 2024 exhibition area.

Fig. 7: Showcasing of SERIS developed BIPV technologies

at the Ministry of Defence Sustainability Day 2024

For further information, please contact:

Dr Carlos CLEMENT

carlos.clement@nus.edu.sg

Dr CHEN Tianyi

tianyi@nus.edu.sg

Srinath NALLURI

srinath.nalluri@nus.edu.sg

Rupendra ARYAL

rupendra@nus.edu.sg

(3)Floating Solar Systems

Dr Jaffar Moideen YACOB ALI, Dr Oktoviano GANDHI, Dr Thomas REINDL

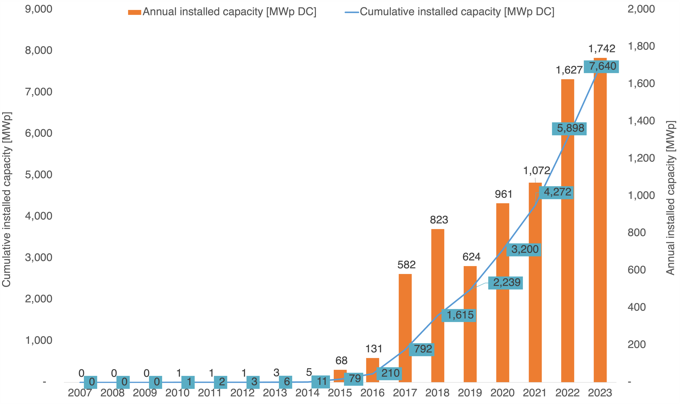

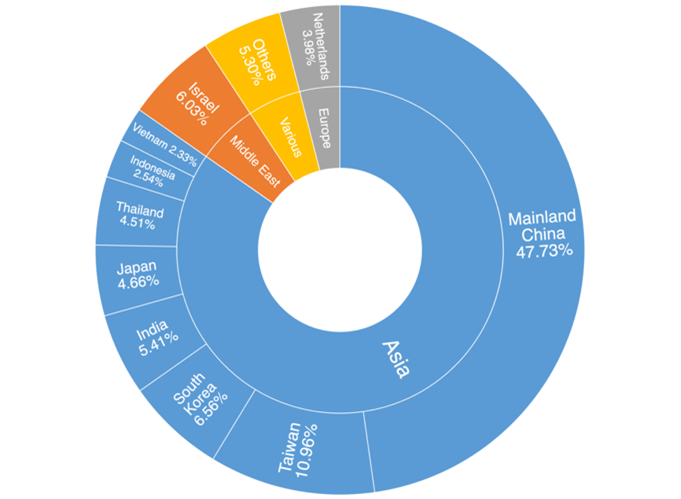

Floating PV (FPV) offers great opportunities for renewable energy generation, particularly for countries with land constraints and available water bodies like Singapore, South Korea, Japan and the Netherlands. At the end of 2023, the cumulative installed global FPV capacity had reached around 7.6 GWp (see Fig. 1).

Figure 1: Globally installed FPV capacity (Source: SERIS FPV database)

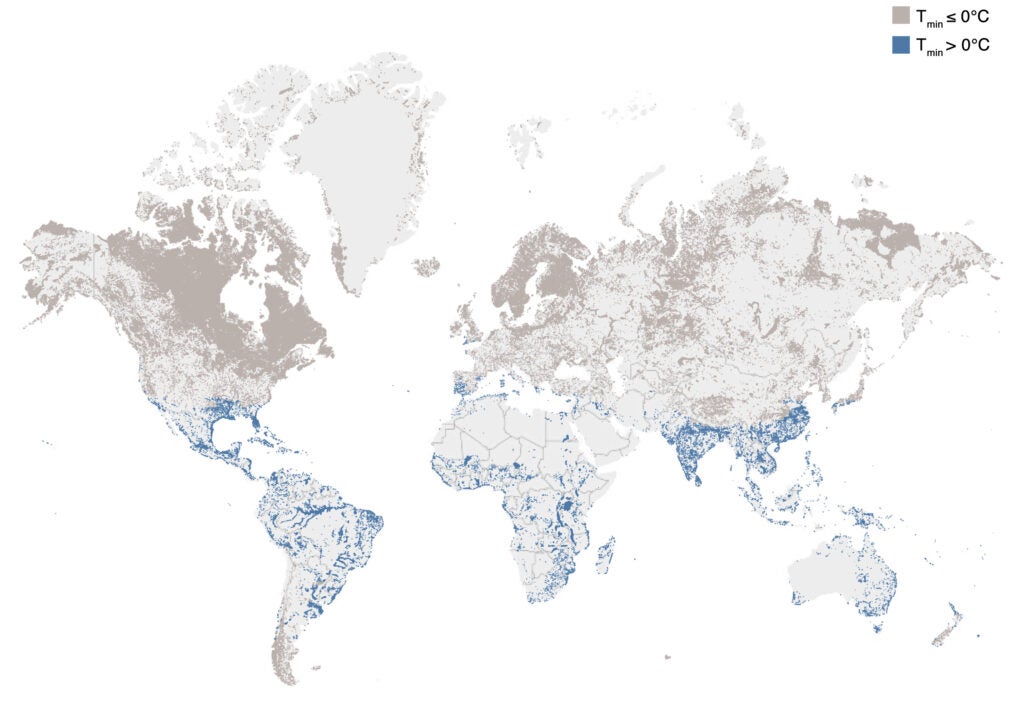

Despite the rapid deployment of FPV systems in the last 10 years, the current global installed capacity is still far below its potential. By covering just 10% of the > 250000 inland water bodies worldwide (see Fig. 2), FPV could reach an installed capacity of ~23 TWp and a potential energy yield of around 25000 TWh/year – which is equivalent to the total global electricity demand in a year (2023 data). This demonstrates the huge potential of reservoir-based FPV in the future.

Beyond that, the potential for marine FPV is even larger. A SERIS assessment showed that, when limiting the ocean regions to those with favourable environment and excluding protected areas, the resulting ocean area spans ~10.6 million km2. By covering just 10% of this area with FPV, the resulting electricity generation would be 6 times larger than today’s annual world electricity consumption.

Figure 2: Global potential of reservoir-based FPV systems

SERIS has been leading the Floating Solar research in Singapore and worldwide since 2016, and has created and maintained a FPV system database of more than 1300 installations to date.

Even though the installed FPV capacity is presently concentrated in only a handful of regions (see Fig. 3), FPV is a global phenomenon, with 63 countries hosting FPV installations at the end of 2023, and many more with projects under development.

Figure 3: Shares of cumulative installed FPV capacity by 2023 by region (Source: SERIS FPV database)

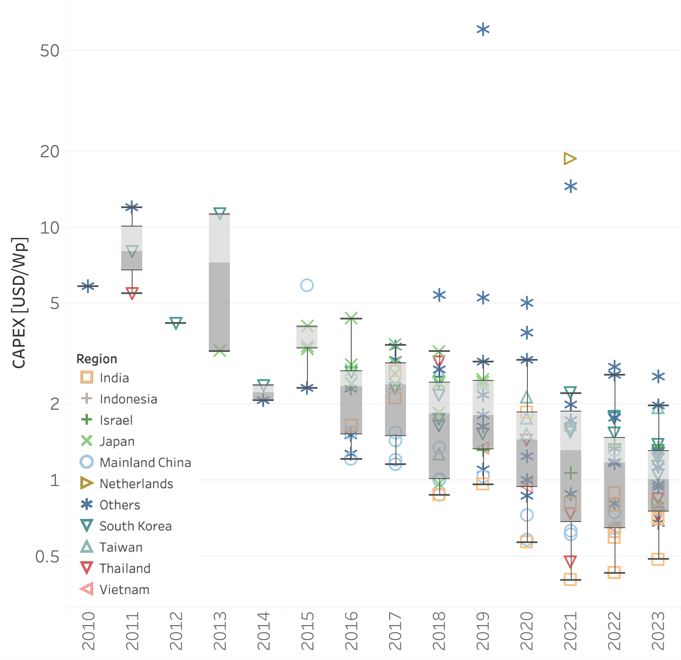

The increase in FPV installations, along with the advancements in technology, has brought down FPV cost from a median of 2.41 USD/Wp in 2015 to 1.05 USD/Wp in 2023 (see Fig. 4), which enabled even wider FPV adoption.

Figure 4: Reported capital expenditure (CAPEX) for existing FPV installations. The values are not adjusted for inflation (Source: SERIS FPV database).

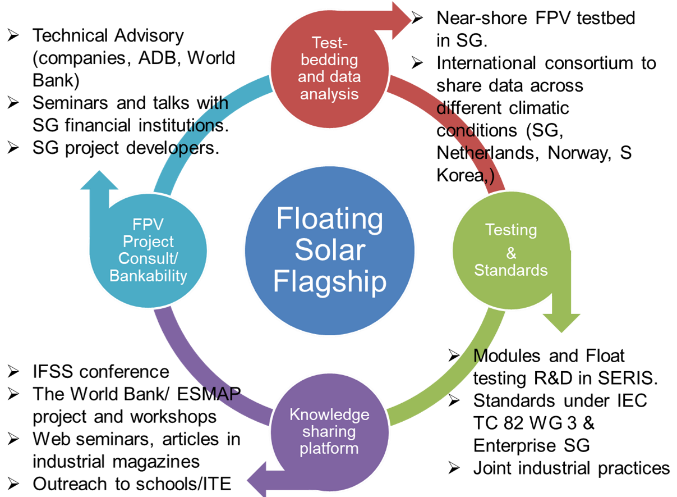

Such insights from SERIS’ FPV database are highly valued by the industry, and regularly shared by SERIS in conferences and exhibitions. To share its knowledge, SERIS also published the “Where Sun meets Water” report series, together with the World Bank Group. As of September 2024, downloads of these reports from the World Bank sharing website (ESMAP) have surpassed 160000. This underlines the high relevance of these reports for the solar industry. FPV industry, which is summarised in Fig. 5 and explained in more detail in the following sections.

Figure 5: Key thrusts of the Floating Solar flagship project

1. FPV test-bedding and data analysis:

Floating PV systems deployed in sea water (either near-shore or off-shore) are the next frontier in scientific PV systems research at SERIS, following a growing interest in Singapore and around the world to utilise marine areas for Floating Solar. This could lead to a virtually unlimited availability of space, provided that there are cost-effective and reliable technologies for deployment as well as for the interconnection to shore. However, this market segment is at a very nascent stage and there is limited information about technical designs, component selection, feasibility, and field data available today to estimate the economic viability of marine-based floating PV systems. Sea conditions pose additional challenges such as higher wind and wave forces (and their combined effects), salinity of seawater, and biofouling that would affect the mechanical stability of the floating structure. Moreover, depending on the distance from the shore and the water depth, the anchoring and mooring engineering becomes more complex and thus expensive. There are solutions available in the marine industry to overcome certain technical challenges, but they need to match the cost levels required by the PV industry to ensure that FPV power is competitive with other forms of renewable energy generation.

SERIS has continued to expand its technical expertise to marine floating solar, and especially near-shore floating PV systems.

SERIS, in partnership with Advario, has won Enterprise Singapore’s Sustainability Open Innovation Challenge (SIOC) 2023. The winning project is based on pioneering self-buoyant and flexible floating PV modules, specifically engineered for near-shore conditions. These cutting-edge modules are designed to revolutionise the deployment, redeployment, operation and maintenance processes, setting new standards in efficiency and adaptability. SERIS will now spearhead a pilot deployment in one of Advario's “dead sea” spaces. This initiative not only underscores Singapore’s commitment to sustainable energy but also positions SERIS at the forefront of floating solar innovation in marine environments.

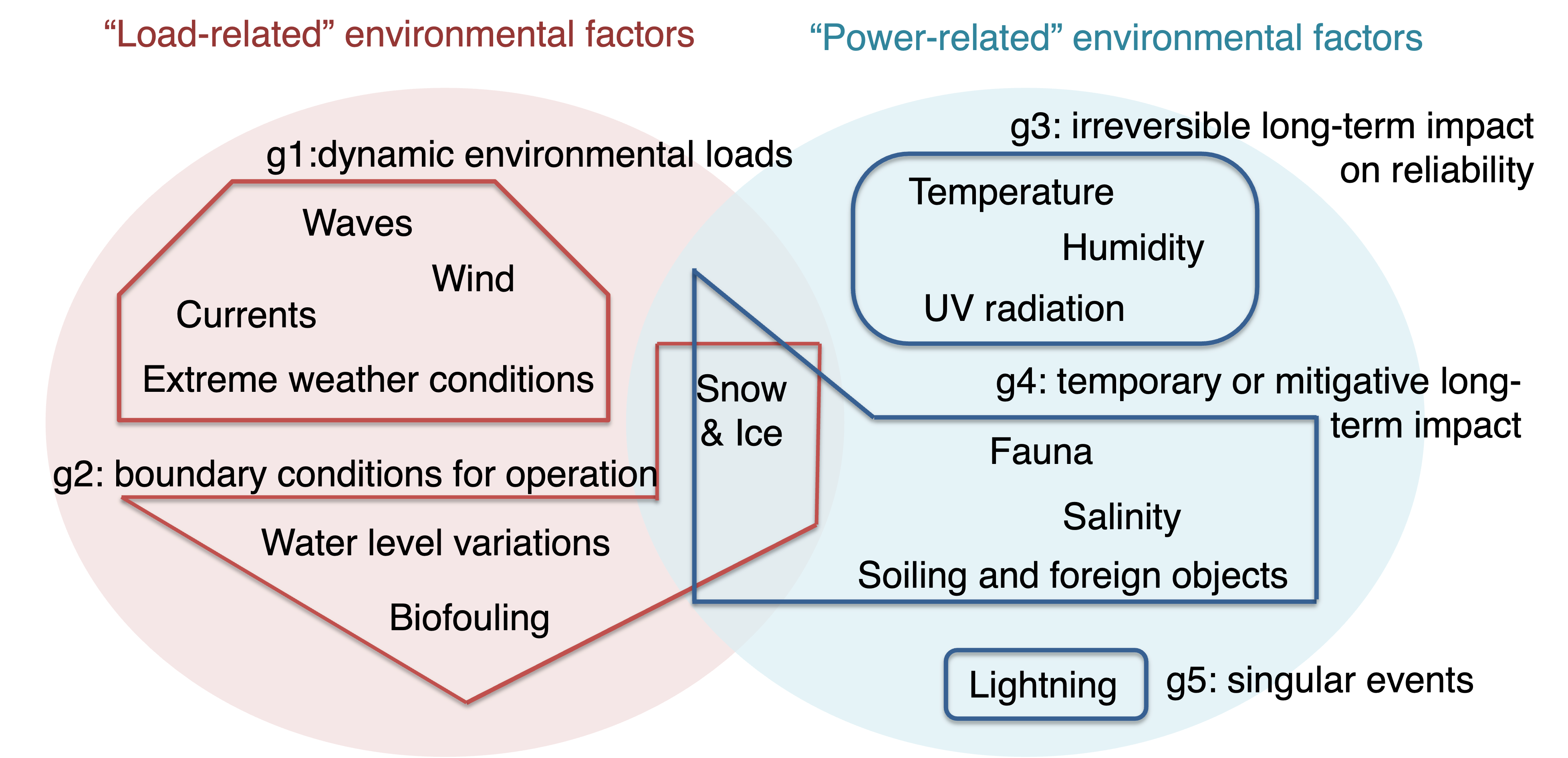

SERIS continues to analyse the operation and long-term reliability of the existing FPV testbeds in the Tengeh reservoir, which in turn helps to better understand the long-term economic viability of FPV systems. Potential environmental causes for failures in FPV systems have been identified (see Fig. 6), and the relationships and inter-dependencies of these causes have also been studied. Moreover, a screening of potential failures associated with these root causes in both sub-system and component level has been conducted, with a specific focus on offshore FPV systems. This very detailed failure mode, effects and criticality analysis (FMECA) study has identified more than 100 possible failure modes as well as suitable mitigation measures.

Figure 6: Environment-related root causes for failures in FPV systems

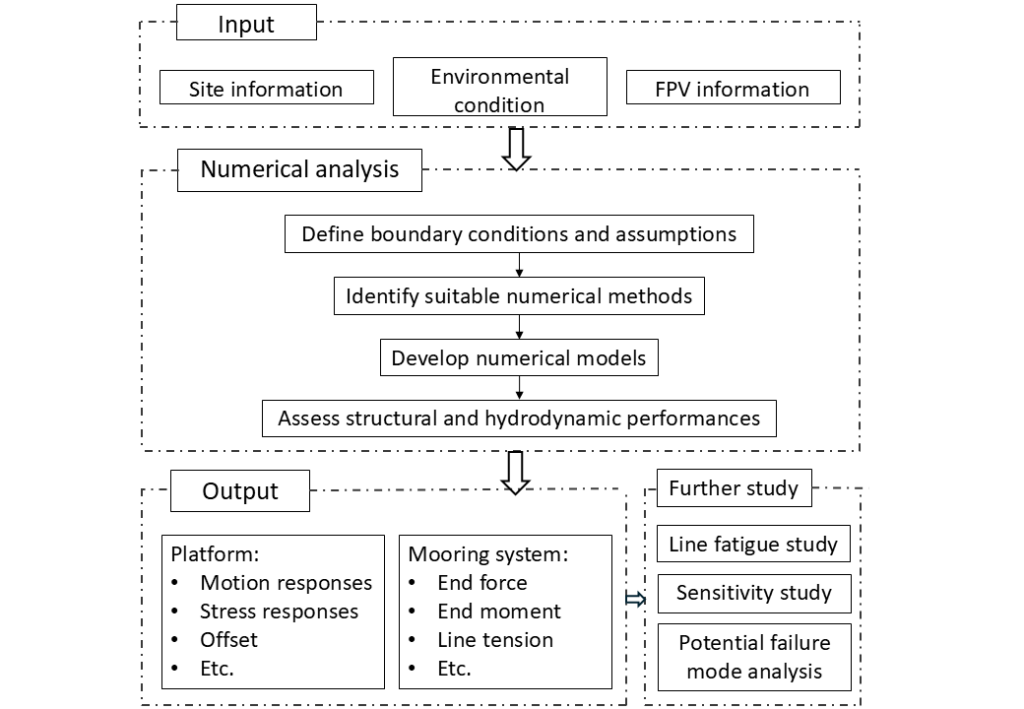

SERIS has also developed simulation models for the numerical analysis of FPV systems, which can assist the development of the FPV system during the preliminary stage. A simplified version of the simulation process for a membrane-type floating platform is shown in Fig. 7.

Figure 7: Simplified workflow for the numerical analysis of membrane-type FPV systems

2.FPV testing & standards:

SERIS has led the preparation and publication of a national standard for Floating Solar systems in collaboration with Singapore’s standard-setting body, Enterprise Singapore (E-SG). The Technical Reference (TR) TR100:2022 on “Floating photovoltaic power plants – Design guidelines and recommendations” aims to further support the industry sector to achieve high-quality FPV installations.

Furthermore, SERIS is spearheading international efforts to establish standards for floating photovoltaics (FPV) through Singapore’s active participation in IEC TC82 WG3. In the first quarter of 2024, SERIS took the initiative to convene the inaugural meeting and introduced the framework for the new IEC 62548-3 standard.

3. Knowledge sharing platform:

As one of the leading research institutes in floating solar, SERIS’ knowledge and expertise are highly sought after in the international PV community. In 2024, SERIS has been invited to major international PV conferences – in Austria, China, Indonesia, Japan, and Singapore – to share the latest trends in Floating Solar, as well as the results of its research on topics such as FPV potential, reliability, and operation.

SERIS has shared its experiences not only with academia and industry, but also with the wider solar community, by giving a lecture on Floating PV at the “PV Academy” event of the EU PVSEC 2024 conference in Vienna and by actively participating in the half-day symposium on “Harvesting Sunshine: Exploring the Future with Floating Solar PV” organised by the Society of Floating Solutions (Singapore).

4. FPV technical advisory :

Although many FPV projects are now in operation or under construction globally, there is still a lack of technical knowledge in the industry. SERIS has been working with major developers and multi-national lenders such as the World Bank Group (World Bank, IFC), the Asian Development Bank (ADB), the Inter-American Development Bank (IADB) and the United States Agency for International Development (USAID) on projects in Singapore, Pakistan, India, Sri Lanka, Vietnam, the Philippines, Suriname, Tuvalu and Mexico to transfer its knowledge to their real-world projects, be it as part of feasibility studies, the engineering design work, or preparation of technical documents for tender specifications. For example, as of 2024, SERIS was involved in the feasibility studies and design of ~2.0 GWp of FPV systems.

Plans for 2025

SERIS will continue to drive scientific excellence and innovation in Floating Solar and continue to share its know-how through technical advisory, international conferences and outreach, as well as scientific publications. Apart from the plans to set up a Floating Solar testbed in marine conditions, SERIS is also exploring the multi-purpose uses of space in near- and off-shore applications. The proposed uses aim to “solve more than one problem for Singapore”, for example the additional generation of fresh produce (i.e., by combining FPV with fish farming and/or crop growing), fresh water (i.e., by combining FPV with desalination), or green hydrogen (i.e., by combining FPV with electrolysers).

For further information, please contact:

Dr Thomas REINDL

thomas.reindl@nus.edu.sg

Dr Jaffar Moideen YACOB ALI

jaffarmoideen@nus.edu.sg

Dr Oktoviano GANDHI

okto@nus.edu.sg