The laboratory is equipped for developing liquid-based functional coatings for solar applications. The equipment enables the synthesis of solutions, vacuum-free deposition of thin films, and their consolidation.

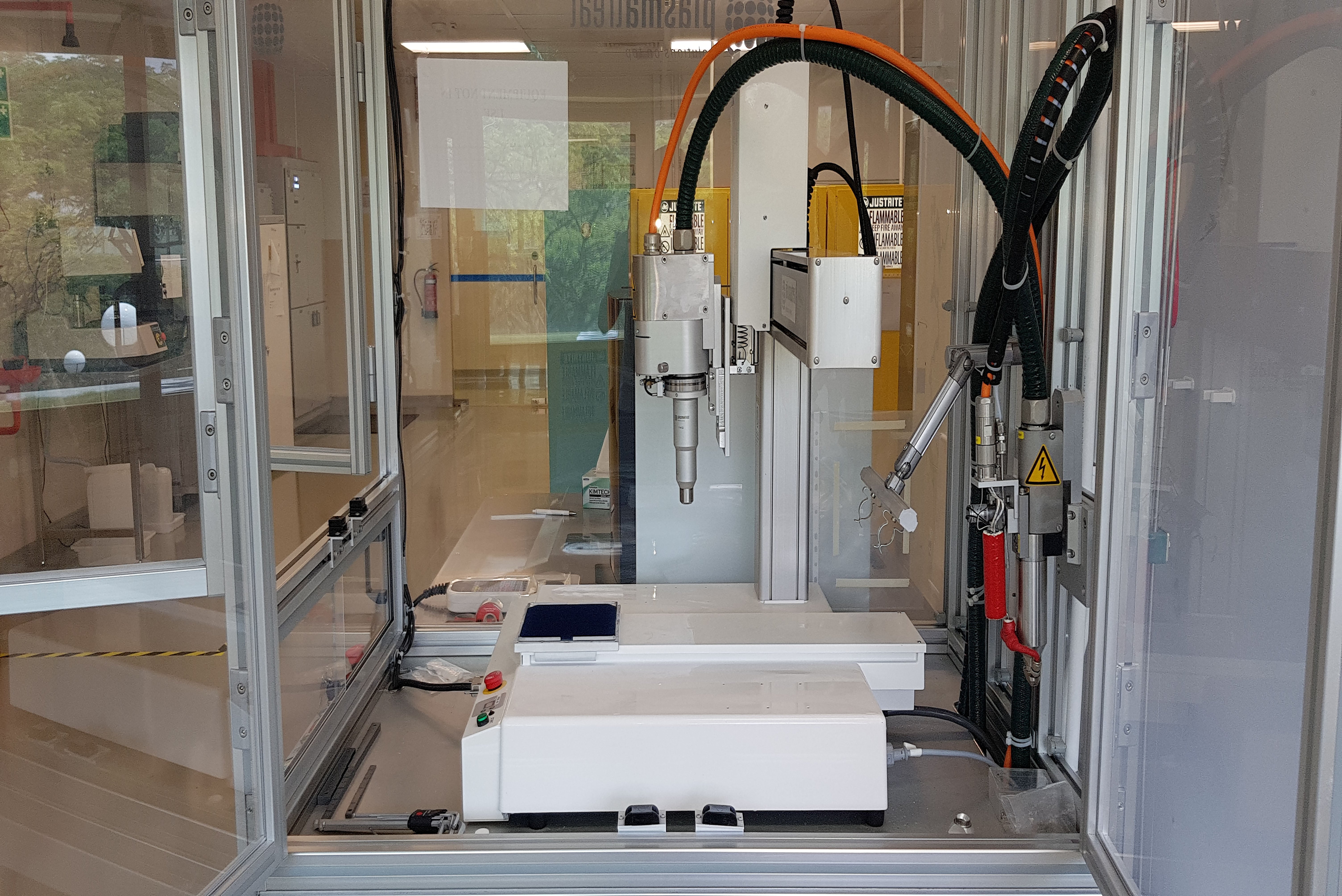

Atmospheric-pressure plasma tool (FG 5001 plasma generator, Plasmatreat, Germany)

The Plasmatreat tool at SERIS is used for plasma treatment of various substrates in ambient conditions, i.e. at atmospheric pressure and room temperature. The tool ionises compressed dry air (CDA) or nitrogen (N2) to create a glow discharge within a plasma jet which is dispensed via a plasma gun. The plasma gun is mounted on a 3-axis robot and can be scanned across the entire surface of a fullsize silicon wafer (156 mm x 156 mm). The ambient plasma treatment has been demonstrated as a low-cost approach to desirably modify surface properties of silicon wafers at various stages of solar cell processing. By combining the Plasmatreat tool with a pumping-evaporator system that supplies liquid or gaseous precursors to the jet heads, a range of functional thin films can also be deposited onto the substrates. An application of this low-cost plasma coating system, currently in development, is the deposition of near-stoichiometric silicon oxide films for applications in passivated-contact silicon solar cells.

Other equipments in the lab:

- Spray coater

- Dip coater

- Spin coaters

- Fume Hoods

- Viscometer

- Furnace