SERIS’ Calorimeter laboratory enables high-precision measurements of the thermal performance of building façade assemblies and fenestration systems, including buildingintegrated PV (BIPV).

Calorimeters are used to accurately measure the solar heat gain coefficient (SHGC or g-value) of complex façade or fenestration systems (including shading devices) and the overall thermal transmittance (U-value). Both values are direct indicators of the energy efficiency of building façades. A low g-value is preferred in the tropics in order to minimise solar radiation heat gain particularly through fenestration systems. High solar heat gains increase the temperature in the building and thus the air conditioning cost. In the tropics, moderately insulated building elements (U-value) are already sufficient to reduce the transmission of absorbed solar heat and ambient heat through the building envelope to acceptable levels.

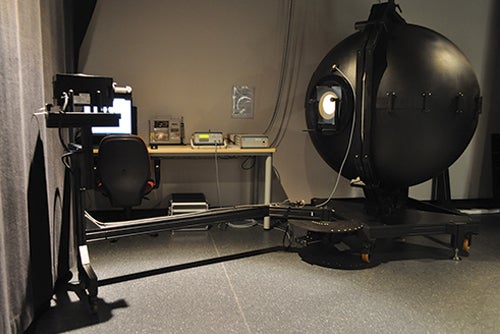

Calorimetric Hot Box

SERIS’ calorimetric hot box is a combined solar heat gain coefficient (SHGC or g-value) and U-value measurement system with the following features:

- Measurement of large, thick, inhomogeneous and non-flat envelope assemblies up to 1.5 m x 1.5 m in size (for example fenestration systems with protruding shading systems, lightredirecting devices or assemblies including BIPV systems)

- For measurements of the solar heat gain coefficient, the sample is exposed to simulated sunlight from a highpowered lamp. The intensity, spectrum, divergence and spatial uniformity of the irradiance at the sample’s surface comply with international standards. Various radiation angles on the sample can be realised, enabling the measurement of the SHGC as a function of the angle of incidence. The thermal properties of the illuminated sample are measured by the calorimetric hot box shown in the photographs.

- For U-value measurements, a climate chamber is put in front of the sample, maintaining the temperatures and surface heat transfer coefficients as required by various measurement standards (for example cool, warm or hot outdoor conditions).

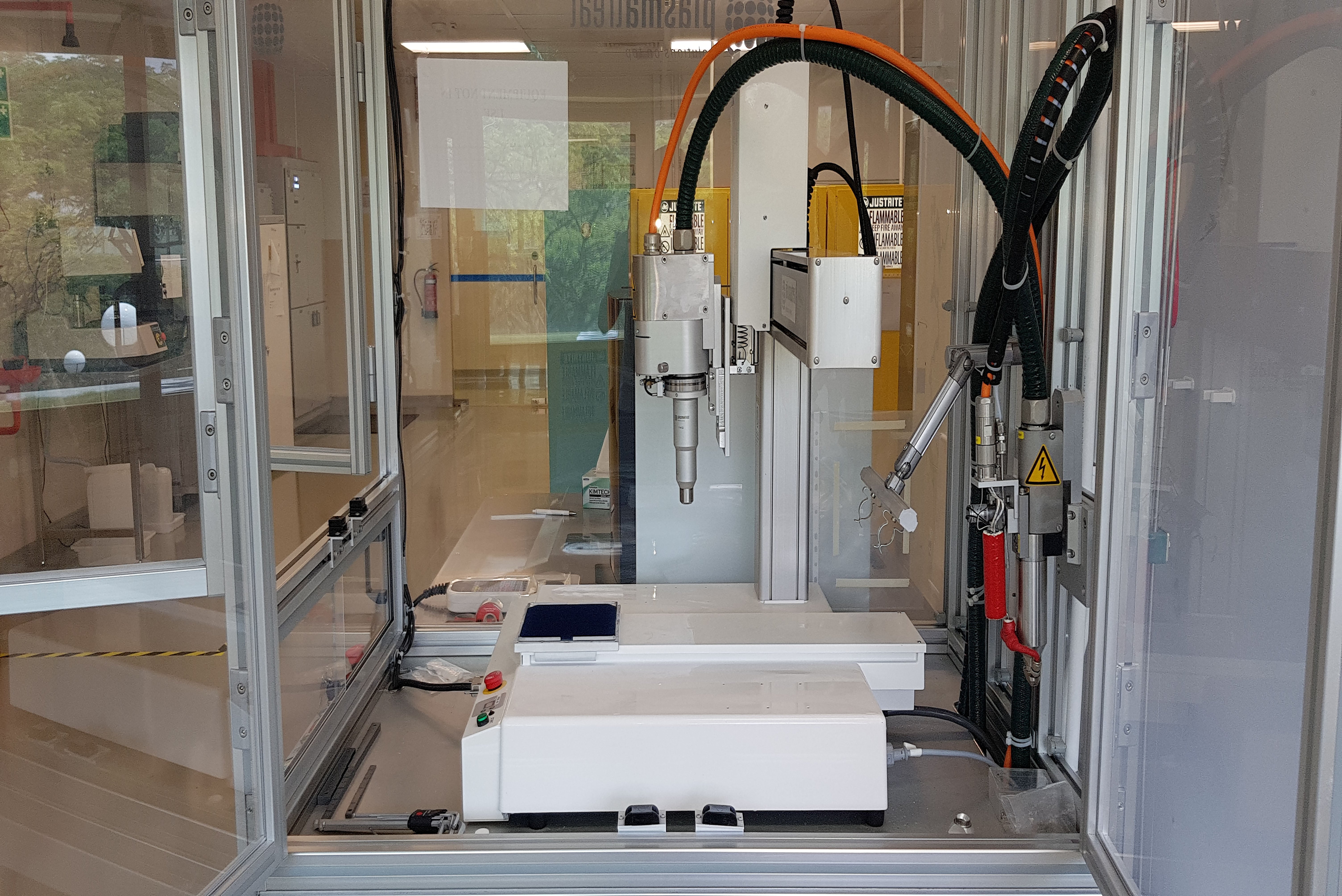

SERIS’ calorimeter is superior to the more commonly used calorimetric hot-plate systems, which are limited to flat samples (as they need to be sandwiched between two plates). It is also superior to the optical determination and calculation of the SHGC with spectrophotometers, which is limited to small, flat and homogeneous samples (and which furthermore requires detailed information the thermal properties of all components/layers of the sample). SERIS’ calorimetric hot box can measure samples ranging from 0.3 m x 0.3 m up to 1.5 m x 1.5 m. The calorimetric hot box at SERIS is designed in compliance with the international standards ASTM C1363 (Test method for thermal performance of building materials and envelope assemblies by means of a hot box apparatus) and ASTM C1199 (Measuring the steady-state thermal transmittance of fenestration systems using Hot Box methods).The large integrating sphere (diameter 1.25 m) system at SERIS was built in compliance to DIN 5036-3 (Radiometric and photometric properties of materials: Methods of measurement for photometric and spectral radiometric characteristics). The system can accurately measure the optical transmittance and reflectance of materials in the visible wavelength range.

For commercially available spectrophotometers, the diameter of the integrating sphere is typically in the range of 6 to 15 cm. SERIS’ integrating sphere is much larger and thus the system has many advantages over standard spectrophotometers. First, it is able to measure large, inhomogeneous and non-specular samples (for example frosted or patterned glass panes, or fabric shading materials). Second, it is able to measure the transmittance and reflectance of samples as a function of the angle of incidence of the visible light. The SERIS system is also able to determine the diffuse and specular components of the optical transmittance and reflectance.