SERIS offers thermographic analysis of PV systems at both system and component levels. This enables the identification of different types of thermal stresses in a PV system. Thermal stress can be a sign of an underlying problem with the PV system, affecting system performance or posing safety risks. We typically focus on:

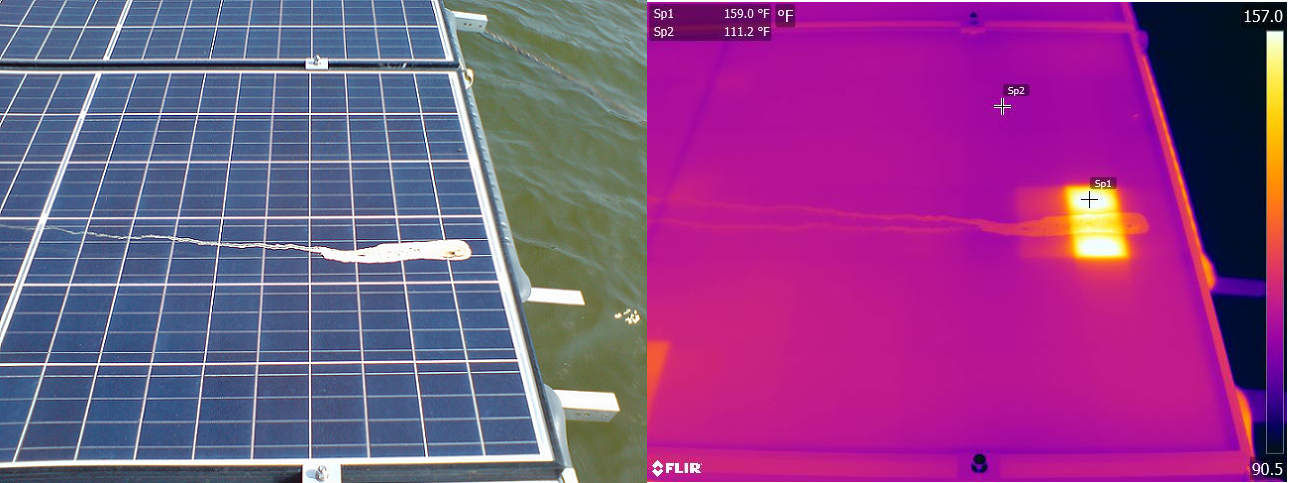

- PV string and module temperature measurements: This helps in determining if a DC string contains damaged PV modules or faulty/overheated solar cells within a PV module (top left picture). Module junction boxes can also exhibit unusual heat behaviour.

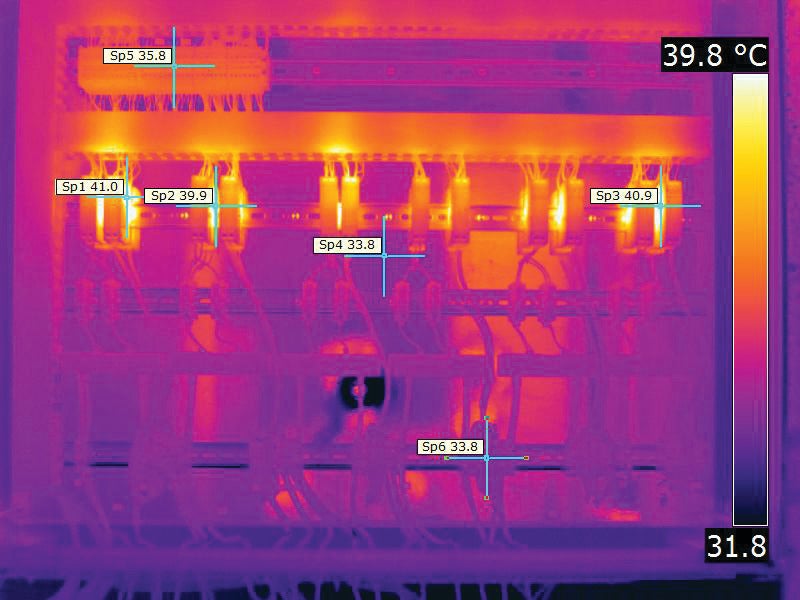

- Component temperature measurements: Component failures not only create PV system downtimes, but they can also pose a fire risk. Proper fuse ratings and component selection for hot temperature conditions are critical but sometimes overlooked. Thermographic analysis provides an in-depth examination of component operating temperatures ranging from DC field junction boxes to AC distribution boards (top middle image).

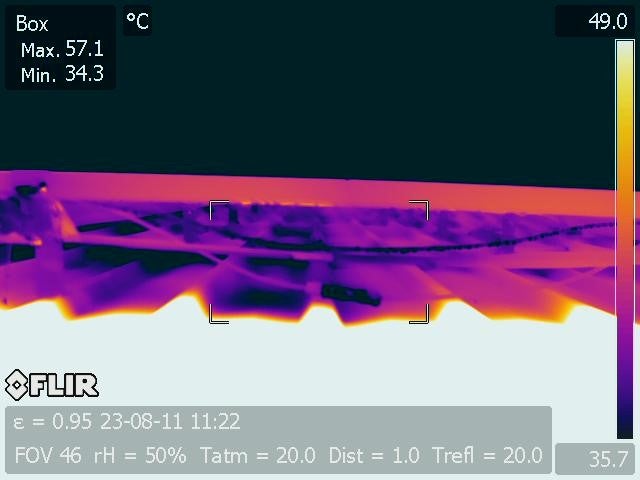

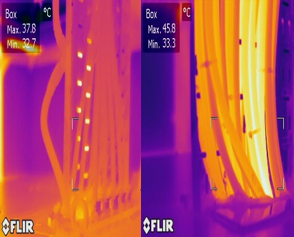

- DC and AC cable operating temperature measurements: Hot spots can be detected not only in system elements that are exposed to sunlight, but also in the wiring configuration. Overheated parts can result from loose connectors and undersized cables (top right image), an overloaded cable tray (bottom left image), improper cable routing (for example cables dangling and touching a metal roof; bottom middle image), and AC cables entering the electric switchgear as a bundle rather than through proper cable glands (bottom right image). These issues reduce the performance of PV systems and increase the risk of a fire.

Silicon PV modules in operation, with some solar cells having a significantly increased temperature (“hot spot”) due to a bird dropping. Left: Photograph. Right: Thermographic image.

Thermographic image of overheated components in a DC distribution box.

Thermographic analysis showing the overheating of a DC cable and a connector.

The main drop-down cable trunking (from the roof to the inverter at ground) is overheating due to overloaded cable trays (all cables) in the trunking. Top: Photograph showing how the trunking is bulging. Bottom: Thermographic image.

Thermographic investigation demonstrating the overheating of 2 DC connectors that are in contact with the metal roof.

Thermographic picture of AC cables entering the electric switchgear.

Left: Thermographic image of cables with proper cable glands and cable routing.

Right: Thermographic image of AC cables entering the switchgear as a bundle leading to overheating due to improper setup.