SERIS’ ISO/IEC 17025 accredited PV Module Laboratory started its testing operations in 2010. Located in CleanTech Park, it has regularly embarked on equipment upgrades and system updates to remain relevant to the changing needs of research centres and the solar industry. In addition to the standard testing, research activities such as on Potential Induced Degradation (PID), measurement of the Incident Angle Modifier (IAM), and reliability of modules for floating PV applications enable the Laboratory to address specific concerns of the research partners. The Laboratory has ISO 17025 accreditation from the Singapore Accreditation Council (SAC) for PV module qualification and safety. It is also accredited for the electrical characterisation of secondary reference standards (“Golden modules”) according to IEC 60904-2, and for the classification of solar simulators according to Edition 3 of IEC 60904-9. The Laboratory offers, among others, the following tests to the industry and to research partners.

Secondary reference standards, temperature coefficients, and irradiance dependence

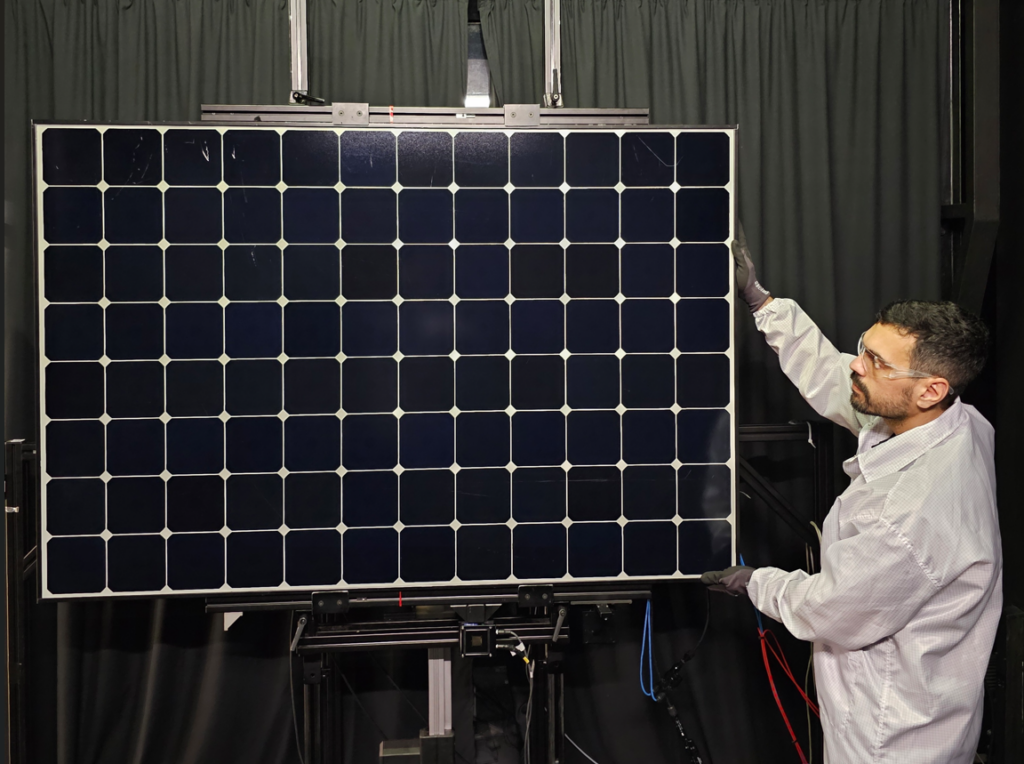

Equipped with two Class A+ large-area pulsed solar simulators (a 10-ms Pasan SunSim 3B and a 100-ms halm solar simulator), the Laboratory can characterise all types of commercially available PV modules at Standard Test Conditions (STC), including bifacial and heterojunction modules. This is particularly important for PV module manufacturers who need a set of secondary reference standards (also referred to as “Golden modules”) to calibrate their own solar simulators on their production lines. In 2024, the laboratory has expanded its scope to cover bi-facial modules, measured according to IEC TS 60904-1-2 Edition 1.0, to meet increasing demand from the industry to measure and characterise such modules.

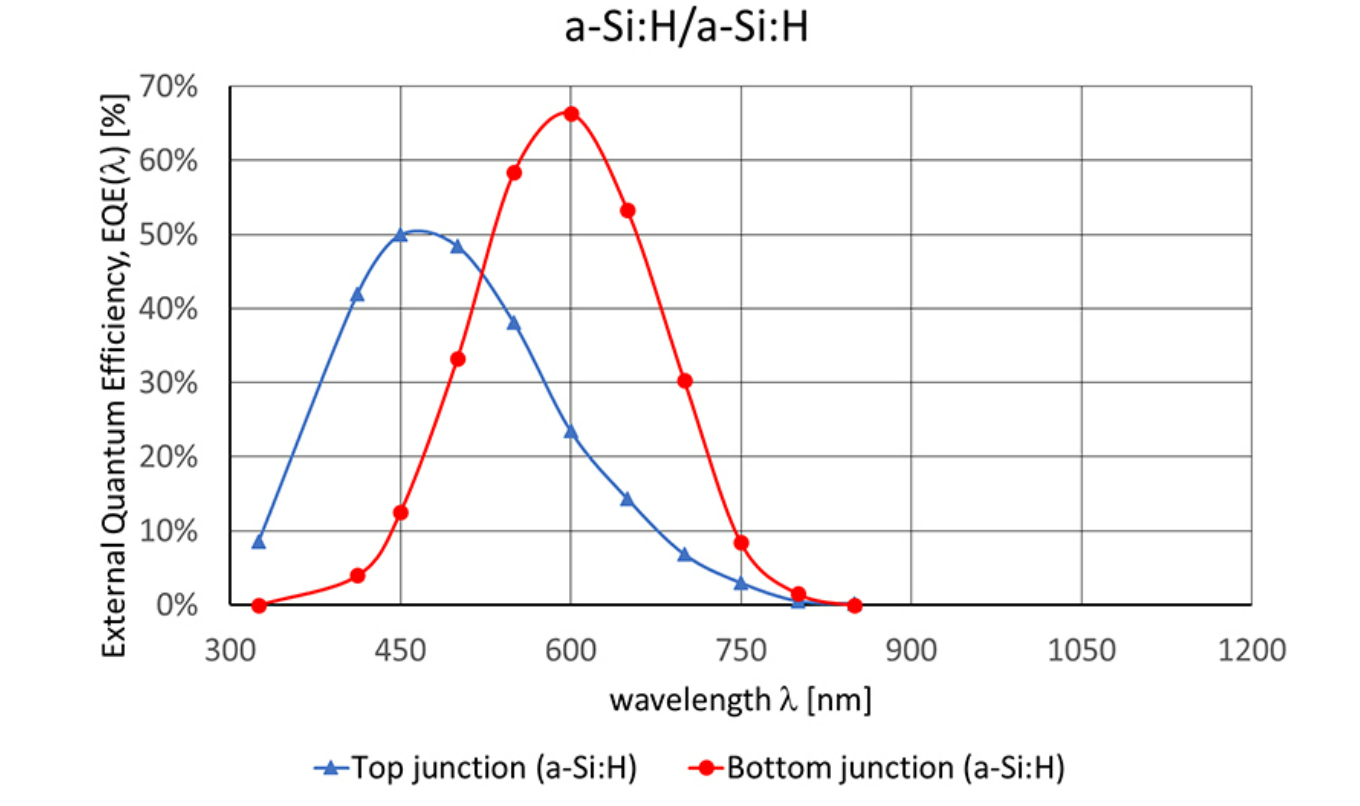

Electrical characterisation of multi-junction modules

In view of the possible emergence of mass-produced multi-junction terrestrial PV modules, and aligned with new frontiers of research on perovskite-silicon tandem solar cells, SERIS’ laboratory is now equipped with an External Quantum Efficiency (EQE) measurement system for multi-junction modules using additional coloured bias light. Validation was performed on an “old-generation” amorphous silicon double-junction PV module.

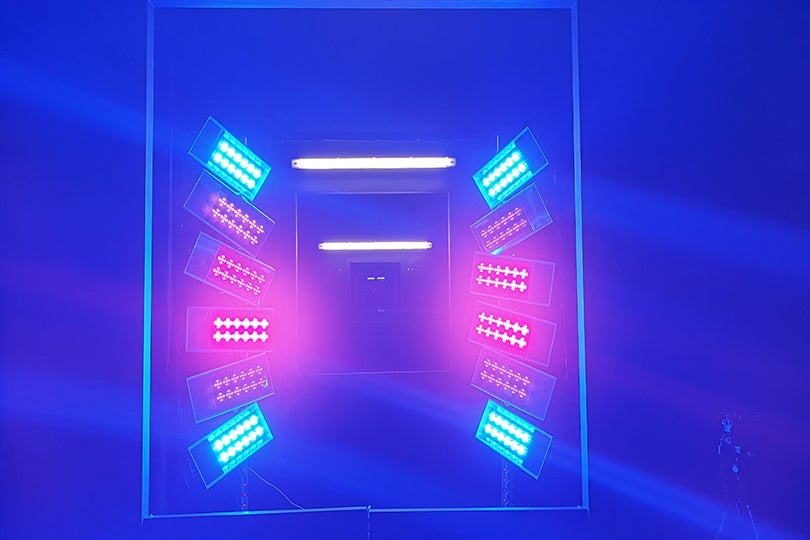

Photoluminescence (PL) of PV modules

Reliability studies often require to detect the origin of failures or degradations in module performance. Electroluminescence (EL) is a well-known imaging technique that allows to easily identify defects such as microcracks, corrosion, or missing/delaminated contacts. In EL the infrared (IR) emission from the cells in a module is triggered by current injection from the module terminals, and hence the method highlights with low IR emission any cell (or parts of a cell) where current flow is missing for any reason. Alongside EL, at SERIS we also perform photoluminescence (PL) analysis, where the IR emission is triggered by photon absorption in open-circuit conditions. The light is generated by powerful LEDs that illuminate the module uniformly. In PL images, the low emissivity areas are not caused by missing current flow, but more inherently caused by cell defects. The combination of PL and EL imaging on the same module can give more insight on the quality of the tested module, and also gives an indication of the root cause for power losses

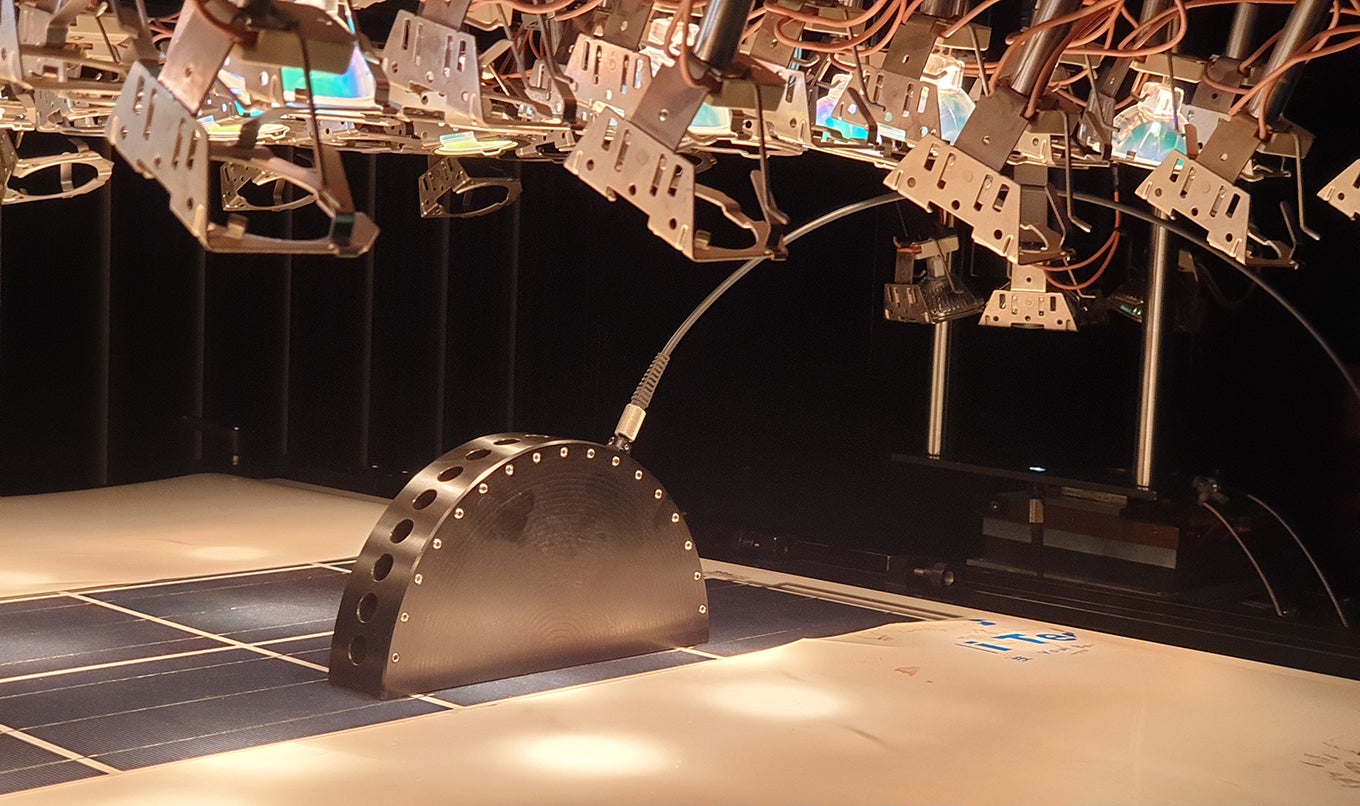

Incident Angle Modifier (IAM)

New PV module architectures, with increasing number of busbars, textured surfaces, smart-wire connections, IBC cells and shingling of cells, have raised the interest in the investigation of the angular responsivity of PV modules. Our Laboratory is equipped with a novel experimental setup to analyse the Incident Angle Modifier (IAM) at full-size commercial module level. The method has been included in the draft of an update to IEC 61853-2 which is expected to be adopted in early 2025.