The PV Module Characterisation & Reliability (PVMC&R) Group at SERIS offers testing of PV modules to the PV industry. It also collaborates in research projects, offering high-accuracy characterisation and consultancy on PV module reliability. The Laboratory is accredited since 2012 to ISO/IEC 17025 for the electrical testing of PV modules. Over time, the Laboratory expanded its accreditation to reliability and safety tests, with special focus on the degradation modes that occur in the hot and humid tropical climate of South-East Asia. In 2021 the Laboratory further expanded its accreditation to potential induced degradation, and the classification of solar simulators. In 2024, the laboratory added the measurement of bifacial modules according to IEC TS 60904-1-2 Edition 1.0 to its scope to meet the increasing demand from industry to measure and characterise such modules. The Laboratory has established collaborations with local and international PV test centres and module manufacturers, being the reference centre for PV module characterisation and reliability for Singapore and the region.

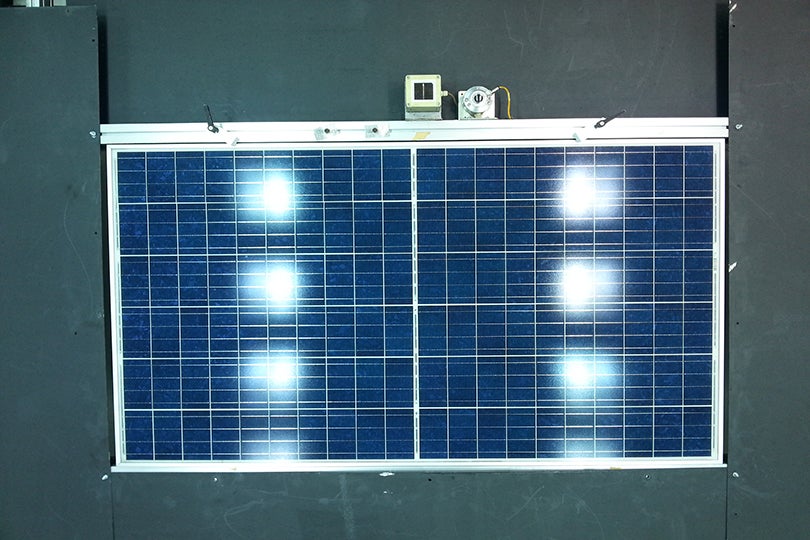

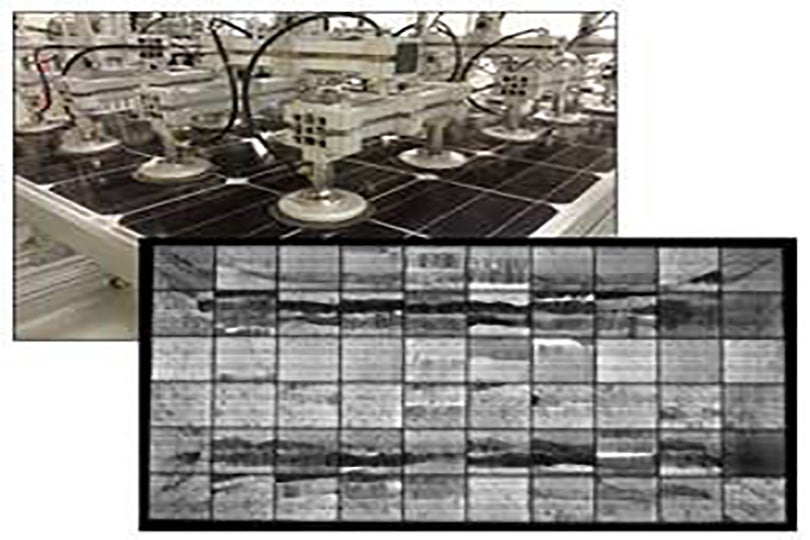

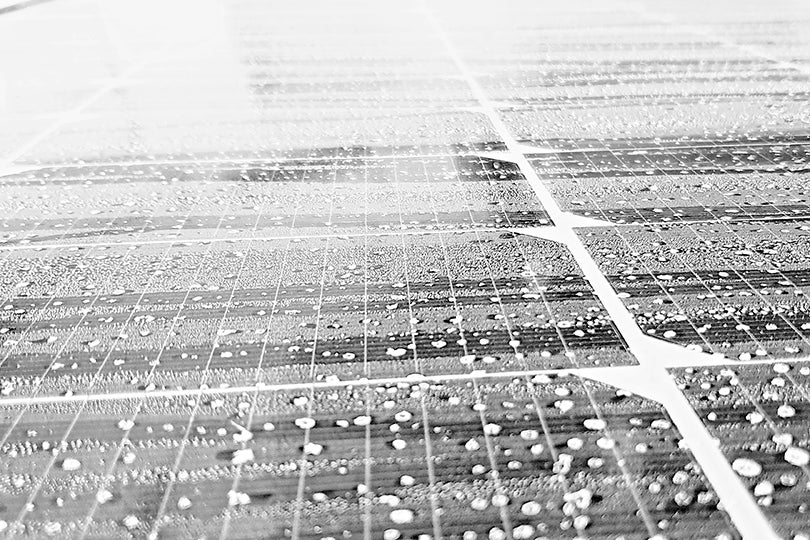

Equipment available in the accredited laboratory

The Laboratory has high-level instrumentation that makes it one of the best-equipped test laboratories in the world for PV module testing, and the top module testing laboratory in South-East Asia.